Manufacture

Our engineers and scientists work in close collaboration with our clients to ensure a cost effective, technically competent solution is delivered. Whether it be the materials selected or the manufacturing process utilised, our experience is certain to save our customers both time and money without compromising on quality.

Core Manufacturing Capabilities:

Screen Printing – Fine line automatic and semi-automatic silk screen printing capabilities permit accurate lay down of various inks, pastes, reagents and adhesives. Coupled with state-of-the-art medical grade drying systems this technology remains capable and cost effective.

Laser Ablation – Our excimer laser tools provide us with a means to produce inter-digited electrodes (IDE’s) and other sensors requiring super fine line and gap dimensions.

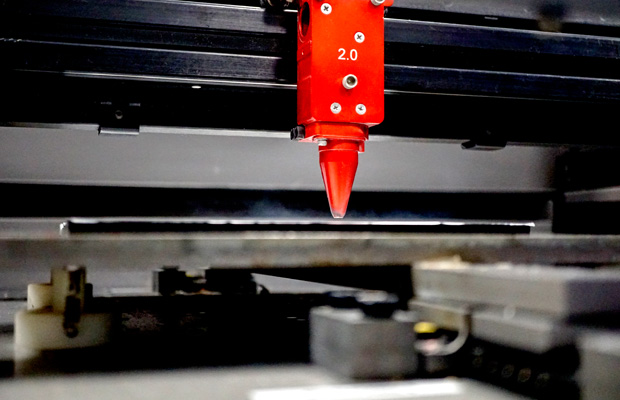

Filling and Sealing – Fluid delivery via blister packs or other innovative solutions is a key competency of FlexMedical. We have several filling and sealing stations which are adaptable via bespoke tooling to meet client specific requirements.