Wearable sensor for continuous Lactate measurement – Step 4

Step 4 – Engineering a Stable Sensor Surface.

Developing a continuous lactate-measuring biosensor for a wearable device involves several biochemical and engineering challenges. A key requirement is stabilising the functionalised electrode surface so it can be successfully integrated into the wearable module.

To operate reliably on-body, the sensor surface must be dried in a stable state and protected by a selectively permeable membrane. This membrane plays a vital role:

- Protects the biochemical surface from contaminants in the sample

- Prevents user exposure to the surface chemistries

- Acts as an “analyte super-highway”, enabling efficient lactate diffusion to the electrode

- Allows soluble by-products of the biochemical reaction to diffuse away

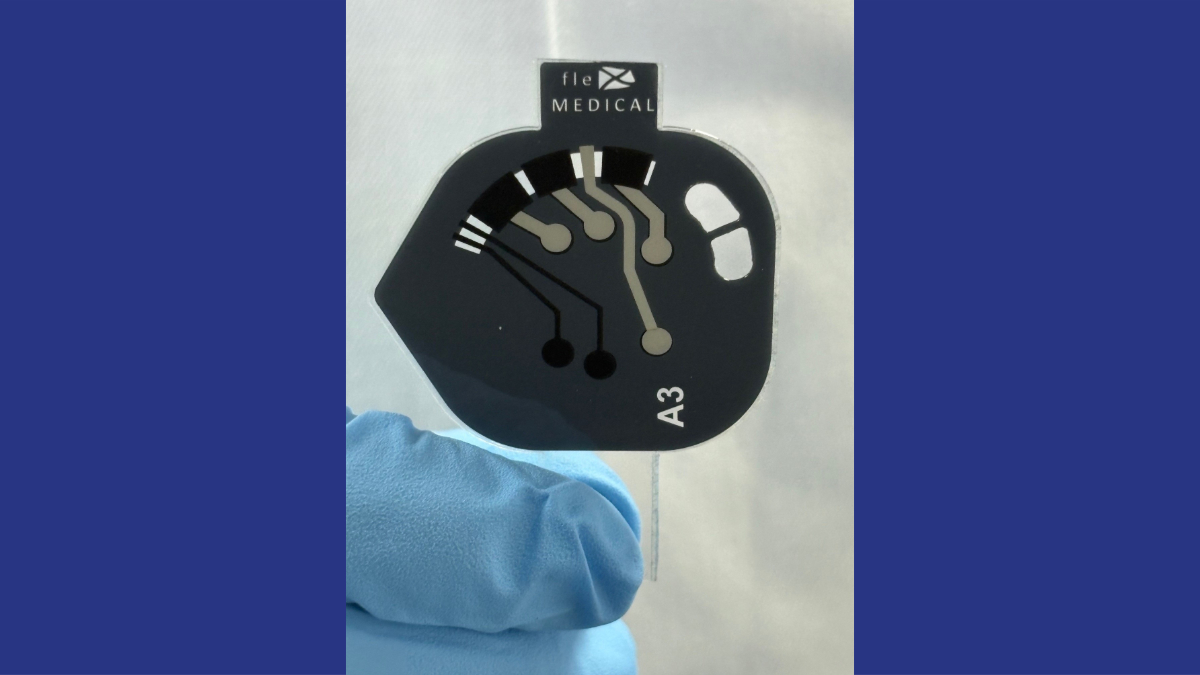

We have now transferred the full functionalization process onto a bespoke electrode array designed for lactate measurement and additional functionality, including fill detection and a second working electrode for supplementary analytes such as pH.

Membrane Development and Early Testing

After multiple design iterations, we’ve established an insoluble, aqueous-permeable membrane that preserves biochemical activity and allows the sensor to be dried. This makes integration into the wearable fluidic module possible, ensuring controlled sweat delivery to the electrode and reliable waste removal.

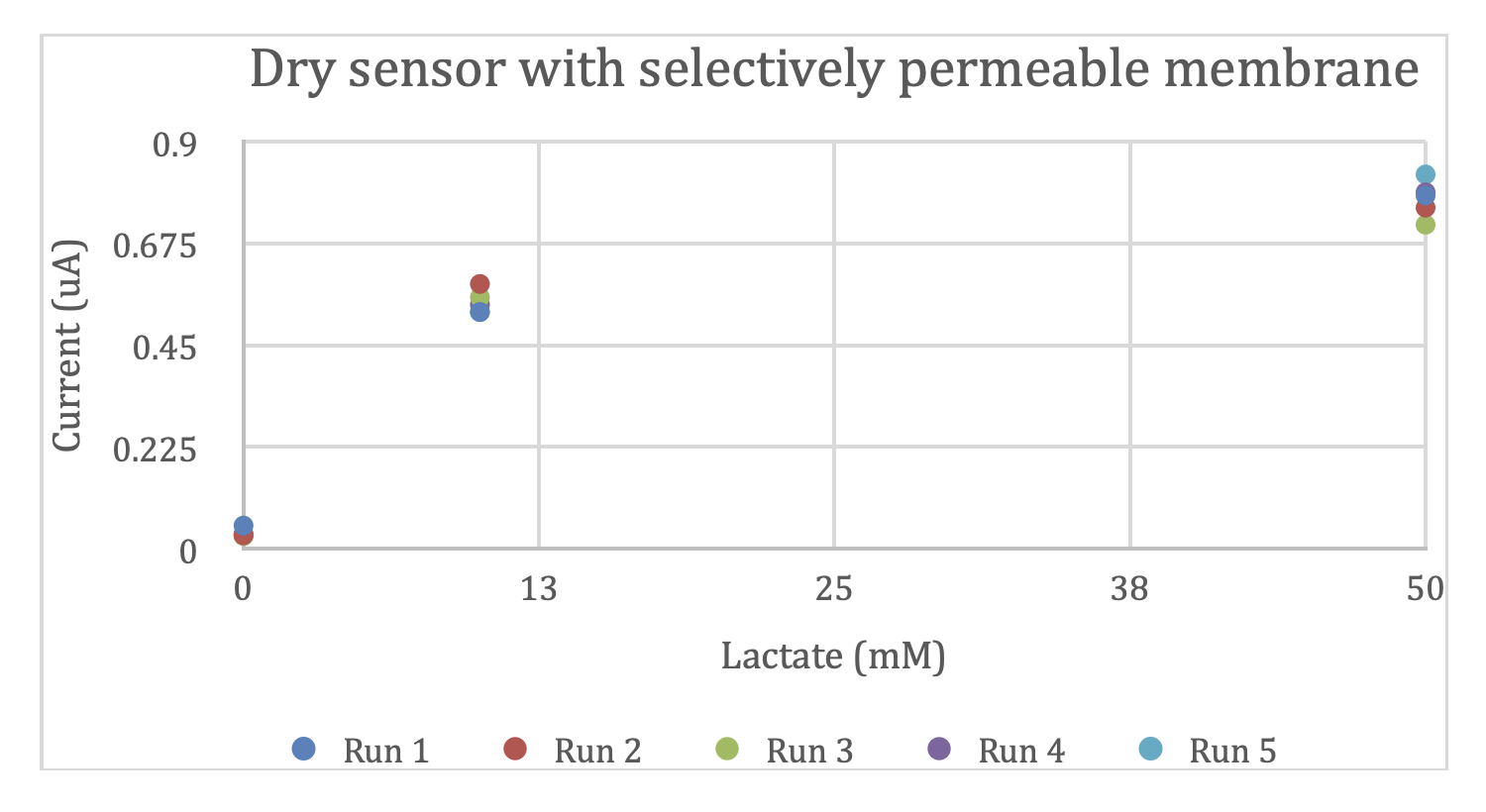

Initial dry-state testing has delivered encouraging results. The example dataset demonstrates sensor behaviour over five repeated cycles at three lactate concentrations (0, 10 and 50 mM). Between each cycle, the sample is washed away and replaced with fresh solution.

Understanding Linearity and Calibration

We’ve also observed reduced linearity at higher lactate concentrations. This behaviour typically indicates that one element in the biochemical pathway is limiting the reaction rate. While raw current responses do not need to be perfectly linear, any non-linearity will translate into increased imprecision at high concentrations once the calibration algorithm is applied.

These findings are normal during biosensor optimisation and help shape our next steps: improving linearity while ensuring precision stays comfortably within commercial requirements.

What’s Next?

In our next update, we expect to demonstrate the complete system working together:

- On-body sweat collection

- In-situ biochemical detection and current generation

- Bluetooth communication to the mobile app

- Conversion to calibrated lactate concentration

- Continuous tracking over time

This is another strong step toward delivering high-performance continuous biosensing technology in a wearable format.