Wearable sensor for continuous Lactate measurement – Step 2

Step 2: perform initial studies on drying of the enzyme and the other key biochemical building blocks required for sensor function.

The final sensor will be stored, shipped and used in a dry and stable format. This is essential for ease of use and long term stability and the removal of the need for cold chain shipping. While the surface chemistry of the sensor will be radically different in the final continuous measuring sensor, the non-continuous (single use) format of the sensor gives us a consistent platform in order to characterize the strategies we intend to use to immobilize, embed, dry and stabilize the final sensor. For this work we use our off-the-shelf carbon electrode that is constructed of the material that are anticipated to be used in the final wearable sensor.

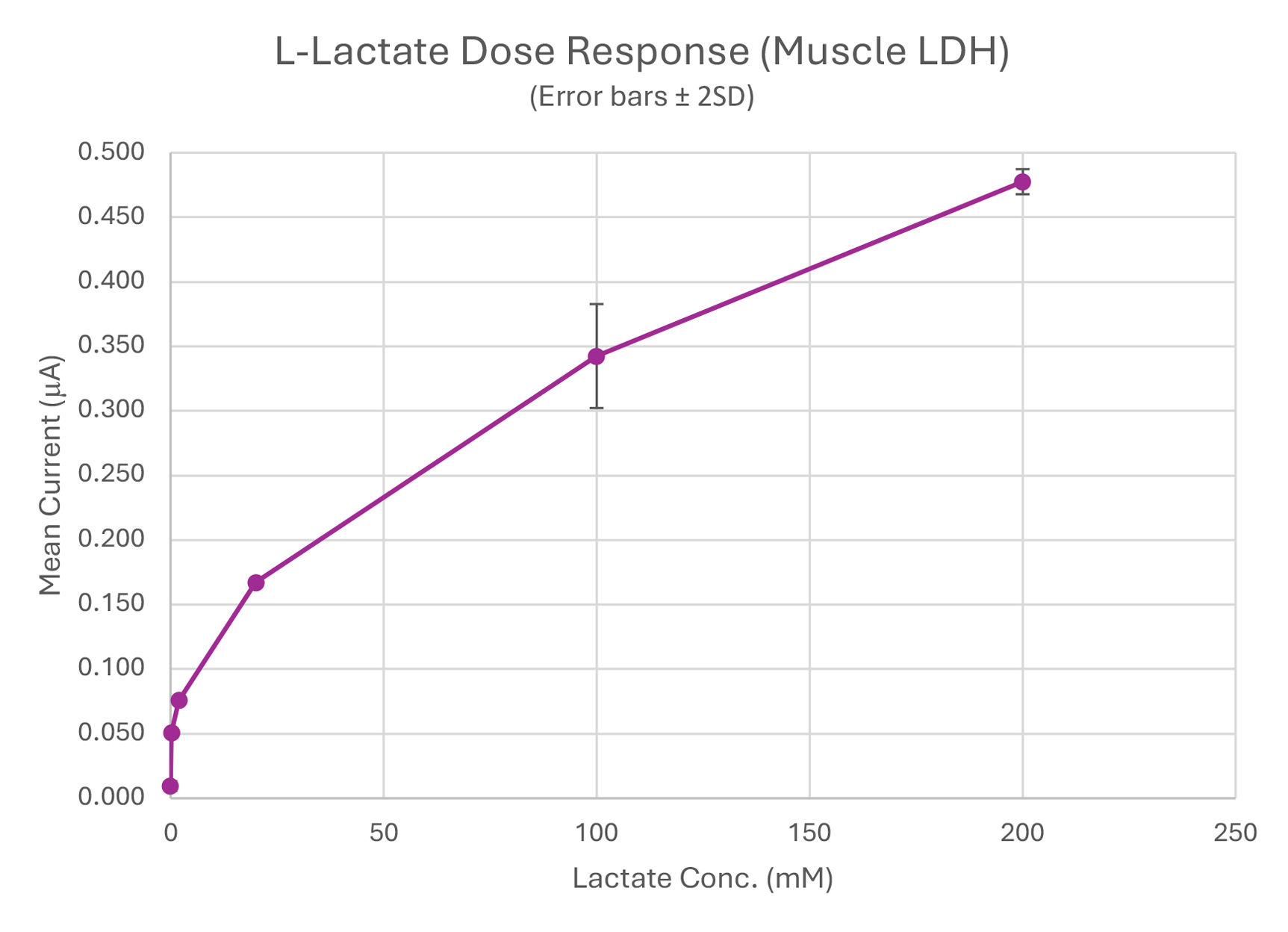

The above dry sensor demonstrated an LOB (limit of blank) of 3.4µM and precision means of 2.0% (raw current) and 7.4% (calibrated response). Dynamic change up to 200mM suggests linearity is expected to be >200mM. This level of performance in a dry sensor exceeded our expectations at this stage in the devices evolution.

Next we move to immobilizing the biochemically active components necessary for the repeated measurement of the biosensors (this is key to the utility of the continuous measurement element of the biosensor). We made rapid progress to this point, we expect things to get more difficult from now to the end of the project.

Donogh FitzGerald

Chief Technology Officer