Wearable sensor for continuous Lactate measurement – Step 3

STEP 3 – one of the key steps in developing a reusable biosensor for lactate measurement is the immobilisation of critical components on the sensor surface.

Why is this important? Traditionally, many biosensors are single-use. We make the sensor reusable, by engineering the key components to be regenerated without losing functionality. This means that when a fresh sample is applied, accurate results can still be obtained across multiple measurements. Our current work focuses on demonstrating this proof of concept, with full performance to be achieved in later stages of design and development.

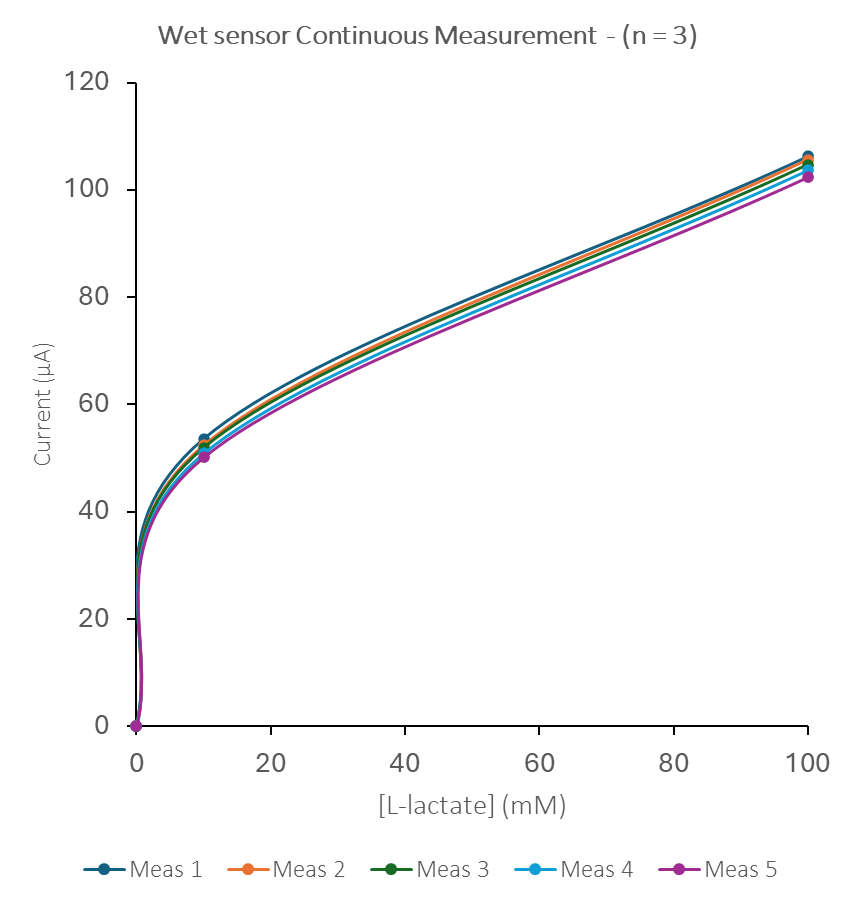

Demonstrating Repeatability

Using one of our in-house immobilisation strategies, we tested sensors at three lactate concentrations. All electrodes were tested, then cleaned with a surfactant-containing buffer, before fresh samples were reapplied. Each sensor underwent five test cycles. Results showed less than 5% variation across the repeated tests – a major milestone, as it was the first time we demonstrated repeatability with reusable sensors and minimal current decay.

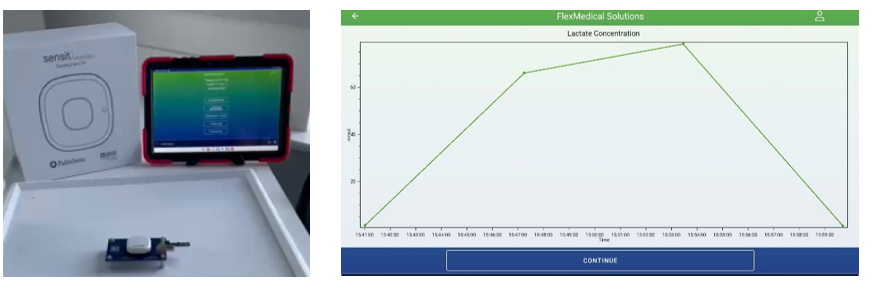

Linking with Our App

We then tested the reusable sensor on the FlexMedical Solutions custom App. In the example shown, four samples were applied in sequence: 0, 70, 90, and back to 0 mM Lactate. Encouragingly, when the final 0 mM sample was tested after the 90 mM reading, the sensor returned to baseline, confirming that results were not biased by the prior high concentration.

What’s Next?

This type of device is referred to as a “wet” biosensor, meaning the biochemical components are immobilised but not dried. Before moving towards a fully dry format, we need to design a semipermeable membrane. This will protect the biosensor from the effects of sweat, skin contact, and mechanical stress, while also ensuring biocompatibility to avoid unwanted skin reactions.

This marks a significant step towards wearable lactate monitoring – an innovation with potential applications in sports performance, health monitoring, and beyond.